David Cornish, Head of Product at Techniche, examines how better charge point analytics can help operators improve uptime.

Recent anecdotal investigations into the reliability of UK EV chargers quote figures which vary from 5% of charge points being out of use to 10% being out of action on a single day.

This is a long way from the UK government’s proposals published in 2022, stating that faults should be repaired quickly to ensure a minimum 99% reliability, on average. While in the U.S, a recent J.D. Power study found that the reliability of the EV charging network is getting worse with at least 1 in 5 charging attempts failing last year.

This level of unreliability gives many drivers charger anxiety and as the cut off point for sales of new petrol and diesel cars looms closer, there’s a risk that unpredictable infrastructure will have an impact on the expected boom in drivers moving to EVs.

What can go wrong?

Due to the complexity of the EV charging ecosystem, there’s a lot that can go wrong – any number of different stakeholders could be responsible for resolving an issue. Visibility of charge point uptime across all parties is difficult too as there is no standard way of calculating it – the technology involved, from hardware to software makes it complicated.

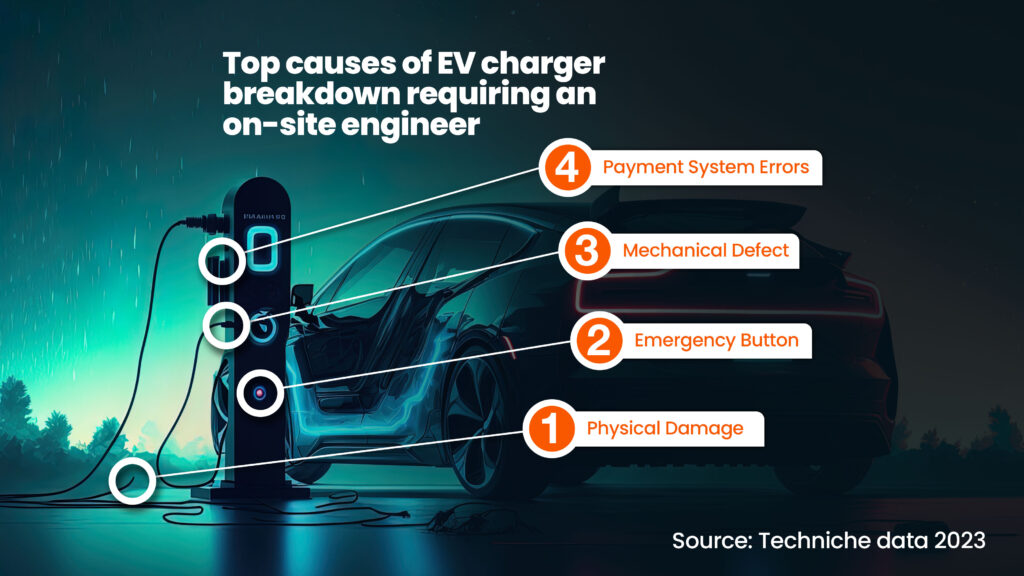

Broken screens, faulty card payment systems, software failures, damaged connectors and electrical connection issues can all bring a charge point down. While older units are more likely to malfunction than newer locations because of weather exposure and general wear and tear, poor-quality maintenance regimes can impact chargers of any age.

Outdated processes

Many operators are still logging breakdowns in a manual, error-prone process, using spreadsheets or a basic ticketing platform not designed for modern asset maintenance management. What follows is a series of emails or calls to triage the ticket between multiple parties, such as the charge point operator, helpdesk, contractor, manufacturer, local authority or energy provider. And while this may work for a small number of chargers, manual handling of maintenance tickets becomes unsustainable very rapidly as charging networks grow.

What’s needed are digital systems to make maintenance an efficient and cost-effective operation. Automated workflows can transform how quickly charge points are repaired, while analytics deliver valuable insight into how reliable a charging network really is.

Benefits of going digital

Automation removes the manual triaging and processing of maintenance work orders, while seamlessly connecting disparate systems. Requests are logged and the relevant teams are alerted automatically that action is needed. A smart solution will automatically dispatch work orders, understand the error code and know which team should be notified to fix an asset. This whole process takes seconds, not days or hours.

The data generated by this digital approach can help answer critical questions: What’s the charger uptime by manufacturer? Are maintenance teams meeting performance SLAs? How many work orders have been raised per charger model?

Knowing the average time between failures of different equipment models means suppliers can be held accountable and benchmarked. Reliability across different vendors, sites, geographies and climates can be compared to understand which equipment performs the best in different environments.

Ultimately, monitoring reliability trends means reduced downtime and a superior customer experience, while longer-term, understanding asset performance leads to smarter EV charger investments, better budget forecasting and planning.

Next steps

If you’d like to learn more about Techniche CMMS for EV charging infrastructure, request a call back or schedule a product demo.

Or if you’d like to read more of our blogs, check out this selection or head to the resources section:

Top five EV charging KPIs and metrics

Are you ready to have your EV charging stations rated or reviewed?